Gold: $3,352.30

Palladium: $975.00

Platinum: $986.00

Silver: $32.69

Gold: $3,352.30

Palladium: $975.00

Platinum: $986.00

Silver: $32.69

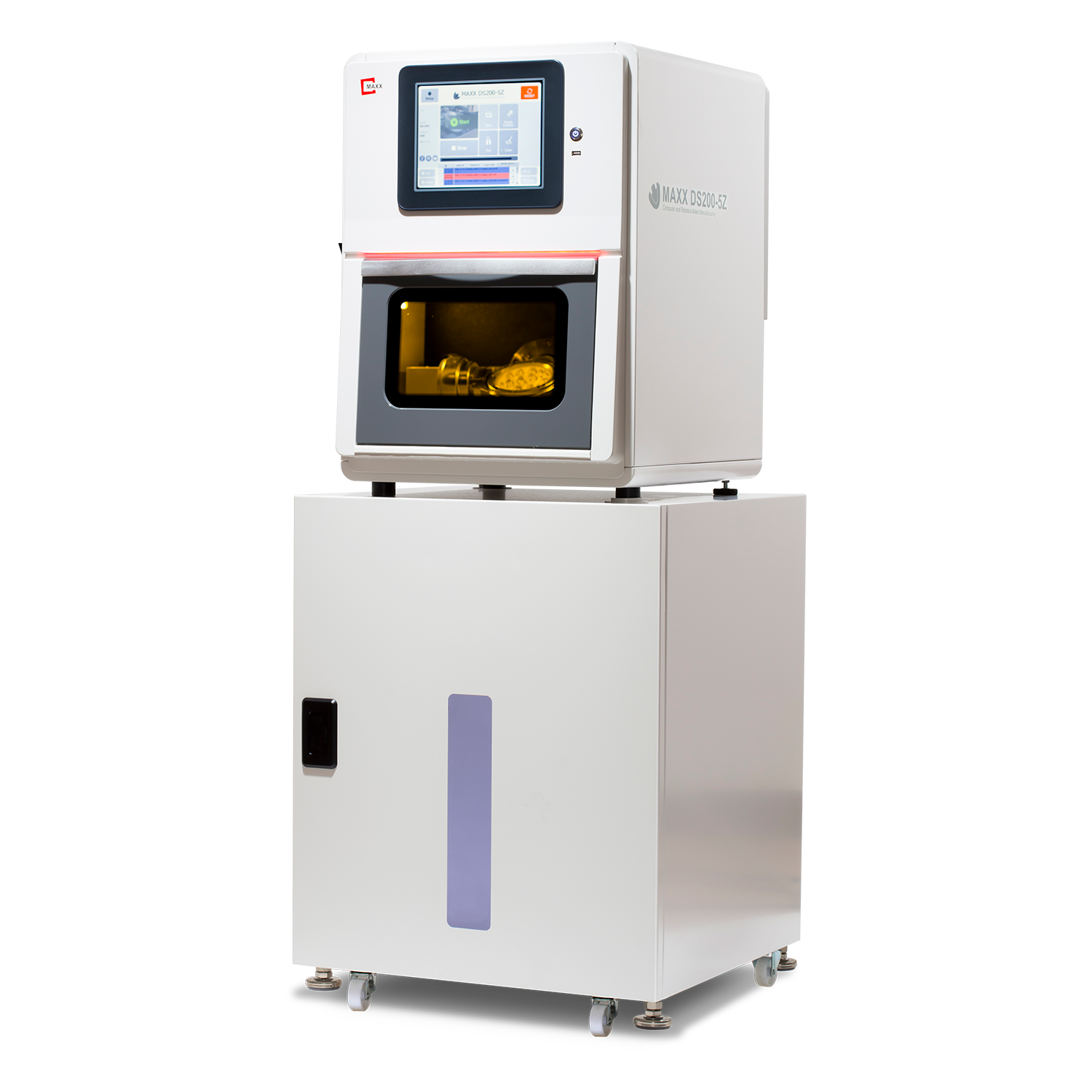

Home > Equipment > Milling Machines > MAXX DS200-5Z

DS200 – 5Z is a 5-axis desktop milling machine and specialized for soft materials. Small and compact, but fast and accurate milling.

Optimized to delicately mill with thin margin. The prostheses that require sophisticated techniques such as facial, undercut, inlay, and veneer can be milled out precisely without chipping.

Zirconia, wax, PMMA, hybrid ceramic, C-type clamp

Our user-friendly software, MAXX continues milling functions to save time. You can have remote services and training and operate the machine through MAXX LINK.

MAXX has more other functions to help the milling process more convenient and safe.

| No. of Axis | 5-Axis |

| Size and Weight | 500W x 682D x 712H, Approx. 100kg |

| Controller and motor | Windows based PC (10.1” touch screen), AC Servo motor |

| Index operating ranges | A=±34deg, B=±180deg |

| No. of tools and tool spec | Shank diameter : 3mm, ATC 12 Tools |

| Spindle | BLDC motor, 500W, 60,000rpm |

| Material & Jig | Zirconia, wax, PMMA and hybrid ceramic, C-type clamp |

| Cooling | Dry |

| Utility | AC220/6A & Compressed air (6.5bar) * Disc (Φ98, height: 10~30mm) and pin-type (6 pins) |

Aurident, Inc.

P.O. Box 7200

Fullerton, CA 92834-7200

Toll Free: (800) 422-7373

Local: (714) 523-5544

Fax: (714) 870-0608

Email: info@aurident.com

Hours

Monday – Friday

7 a.m. – 5:00 p.m. PST

Copyright © 2025 Aurident, Inc. All Rights Reserved